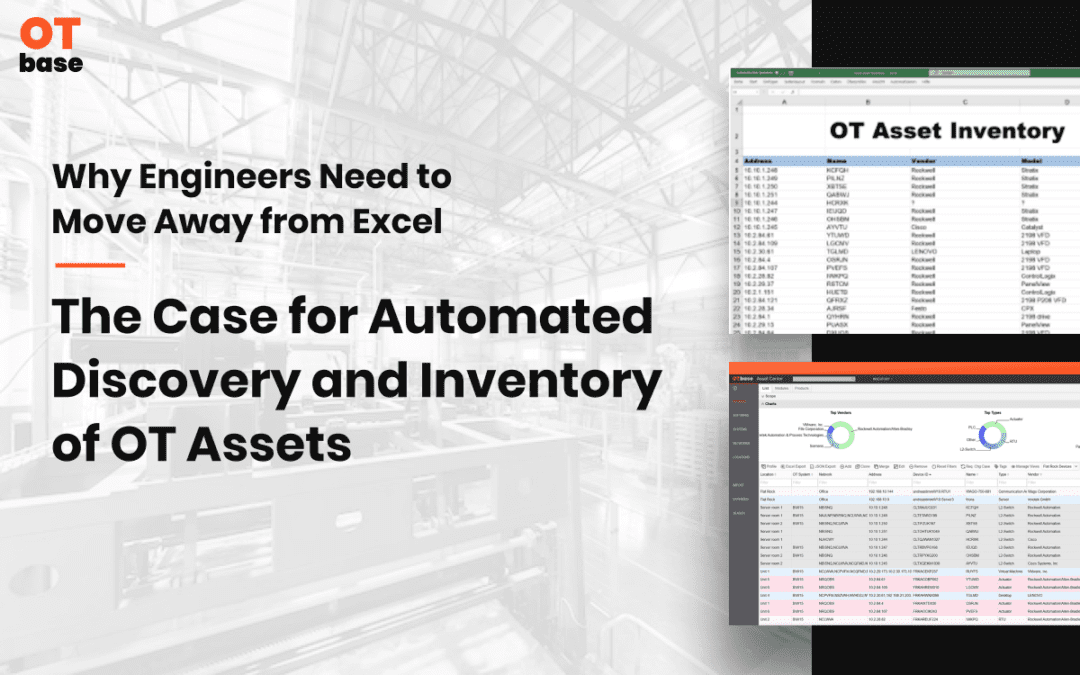

Excel spreadsheets have been the go-to tool for engineers and operations teams for years when managing their OT asset inventory. While spreadsheets are useful for basic tasks, they are no longer sufficient for the complex requirements of modern OT environments. The increasing complexity of OT networks and the need for real-time visibility and automated monitoring mean that engineers must move away from Excel and adopt a more automated way of discovering and inventorying their OT assets and networks.

Here are a few reasons why engineers need to move away from Excel and toward more automated solutions:

1. Manual inventory is prone to errors

Manual inventory using spreadsheets is a time-consuming and error-prone process. Inaccurate or incomplete information can lead to security risks and poor decision-making. With automated inventory solutions, errors can be minimized, and accuracy can be improved. Automated inventory solutions can automatically detect and identify all the devices and software applications connected to an OT network, providing a comprehensive and up-to-date inventory.

2. Lack of real-time visibility

Excel spreadsheets are static and cannot provide real-time visibility into the state of the OT network. In today’s complex OT environments, real-time visibility is essential for identifying and mitigating security threats. Automated inventory solutions give engineers real-time visibility into their OT networks, enabling them to detect anomalies and respond to security incidents on time.

3. Difficulty in scaling

Excel spreadsheets are not scalable and become difficult to manage as the OT network grows in size and complexity. As the number of devices and applications connected to the OT network increases, manual inventory processes become more time-consuming and complex. Automated inventory solutions are designed to scale with the OT network, providing accurate and up-to-date information regardless of the size or complexity of the environment.

4. Compliance requirements

Most industries have regulations and standards that require accurate and up-to-date inventory information for their OT networks. Using Excel spreadsheets to manage this inventory can be a compliance risk, as there is no guarantee of the accuracy of the information. Automated inventory solutions provide accurate and up-to-date inventory information that can help organizations comply with industry regulations and standards.

In conclusion, engineers must move away from Excel spreadsheets and adopt more automated solutions to manage their OT asset inventory. Automated inventory solutions can provide real-time visibility, accuracy, scalability, and compliance, which are essential for modern OT environments’ complex requirements. By automating the inventory process, engineers can free up time to focus on other critical tasks, improve accuracy, and reduce the risk of security incidents.